FREQUENTLY ASKED QUESTIONS

Eurocap & Eurocork attaches particular importance to customer service. To assist our customers in the best possible way, we have listed some frequently asked questions with clear answers. If you need additional information, please get in touch with our product experts; they will be happy to help.

Contact us

FAQ 1 | How can I tell if a crown cap is crimped properly on a bottle?

Optimal crown cap closure is essential to preserve your drinks properly. To check the crimping, we offer metal check plates that allow you to quickly and easily check whether the crown cap is too tight or too loose around the bottle opening. How to do this:

Crown corks 26 mm

For correct crimping, the diameter of the crown cap should be between 28.57 mm and 29.00 mm.

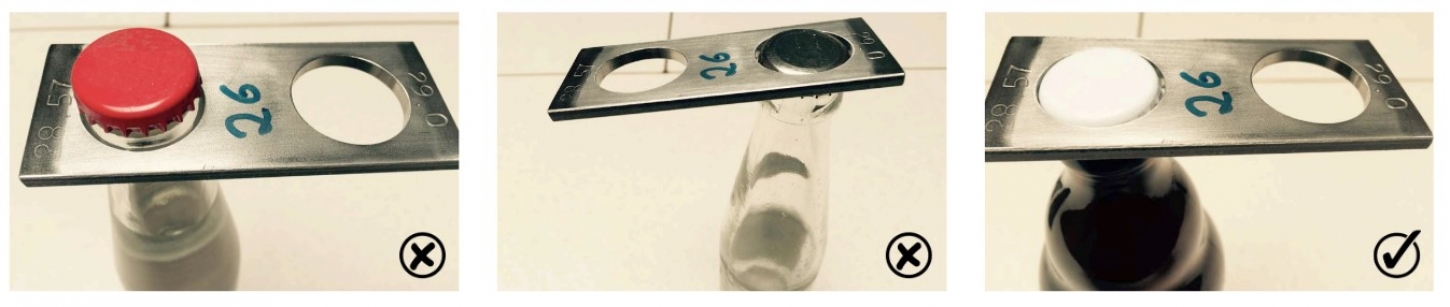

Step 1 | Place the check plate’s opening (28.57 mm) on the crown cap.

- Is the opening too large, and does the plate fall over the bottleneck? This means that the crown cap has been over-crimped. This risks damaging the bottle and causing rust and sealing problems.

- Does the opening of the check plate rest on the teeth of the crown cap, making the plate level with the crown cap surface? Then the crown cap is crimped correctly.

Step 2 | Place the check plate’s opening (29.00 mm) on the crown cap. If the opening does not fit the crown cap, the crown cap is not sufficiently crimped, which increases the risk of rusting and sealing problems such as gas loss and leaks. The crown cap could also come loose.

Crown corks 29 mm

For correct crimping, the diameter of the crown cap should be between 31.40 mm and 21.60 mm.

Step 1 | Place the check plate’s opening (31.40 mm) on the crown cap.

- Is the opening too large, and does the plate fall over the bottleneck? This means that the crown cap has been over-crimped. This risks damaging the bottle and causing rust and sealing problems.

- Does the opening of the check plate rest on the teeth of the crown cap, making the plate level with the crown cap surface? Then the crown cap is crimped correctly.

Step 2 | Place the check plate’s opening (21.60 mm) on the crown cap. If the opening does not fit the crown cap, the crown cap is not sufficiently crimped, which increases the risk of rusting and sealing problems such as gas loss and leaks. The crown cap could also come loose.

FAQ 2 | How do you prevent crown caps from rusting?

Non pasteurized products

In order to reduce the risks for the rust formation before and after filling, we suggest the following:

- to store the crown closures and the finished product in a dry and airy place, with humidity rate below 60%.

- After filling, to use air blowing conveyors placed at 45° upwards, allowing the internal part of the crown cap in touch with the neck-finish to dry. Those conveyors are installed before the labeller at a distance of 3 cm from the crown cap on both sides of the belt, where the bottles can run on one row and possibly turn on themselves (The number depends from the speed of the filling line). Generally we suggest to install at least 3 each belt side and , what is more important, to have them fitted not regularly, adding a further air blowing conveyor at 2 cm from the top of the cap, always placed at 45° and mounted at the opposite side of the arrival of the bottles.

- Filling conditions suitable in order not to damage the external protection films of the crown cap. Generally we suggest for a neck-finish of 26,5-26,6 mm a capping diameter of da 28,6-28,8 mm. Furthermore it’s important to check that the capping cone is in a good state, since if it is damaged it can take away the protective varnishes on the skirt teeth of the cap.

- For those who use new bottles, to require to the glass supplier that the quantity of coating is maximum 10 CTU.

Pasteurized products

In order to reduce the risks for the rust formation before and after filling, we suggest the following:

- Follow the same instructions as for non-pasteurised products.

- To check that the water used for the pasteurisation have neutral Ph.

- Possibly to use special films (already prepared with holes) allowing the leakage of the condensation formed after the pasteurisation.